Mole vs. horizontal drilling rig

We sometimes encounter the question about which technology and machine is better: horizontal directional drilling (HDD) or mole? Which machine is more versatile. Which one will meet the customer's expectations? Which machine is worth starting the adventure with trenchless techniques. The answer to this question seems very simple: such a comparison misses the point, because each of these machines and technologies has a completely different application. There is, of course, a certain group of earthworks in which both technologies can be used, but one of these technologies will always lead the way, taking into account the time and cost of implementation, development conditions in the close vicinity of the work site and other less important components. The better technology will be the one that, at any given time, allows for a more efficient, easier and cheaper installation. The better one will be the one that, in a given installation project, is best suited for it, or even suitable as the only one of the two, having taken into account economic and capability aspects.

When considering which of these technologies is better, another example from everyday life, close to everyone, comes to mind. Namely, what is better: a car or a van? The answer is as simple as in the case of comparing HDD technology to pneumatic jacking: that car will be better, which will allow the task to be fully completed at the lowest cost and whose use is allowed by the environmental conditions of the task.

To complete the topic, in the following section we present basic data on the capabilities and application of both techniques of trenchless installation.

PNEUMATIC PIERCING

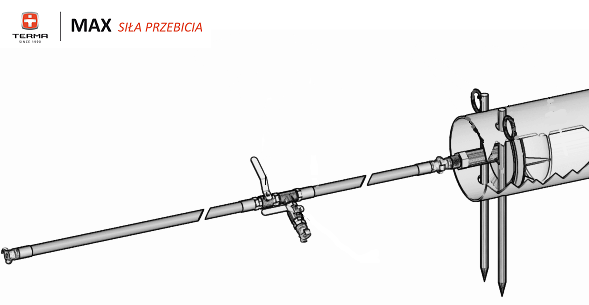

Otherwise known as a mole, a piercing machine, a jacking machine, a ground rocket. It is used for the most common work, which is the routing part of installations of any type, under the existing infrastructure/surface, without the need to dismantle the infrastructure/surface. The most common are installations over a distance in the range of 5 to 20 meters. A typical diagram of such an installation is shown in Figure 1.

Figure 1

Typical application of pneumatic piercing machine

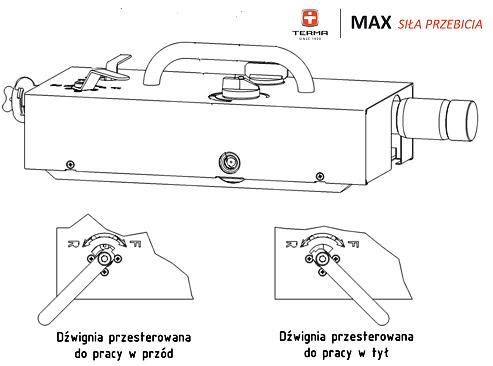

Occasionally there are longer installations, reaching up to 40 meters and more. Here, it is worth mentioning, the most common question is - what about accuracy? After all, the mole is not a machine that can be controlled, either horizontally or vertically. You can only control the direction of operation FORWARD / BACK. Well, theoretically, a machine such as a mole, without the ability to control (in HDD drilling machines we have control), having encountered an obstacle, can change direction. However, in practice, it turns out that a change of direction that makes it impossible to perform the installation as originally intended happens extremely rarely and only where we have really extremely difficult ground conditions. In such difficult ground conditions, any other technology would also have feasibility problems. The vast majority of installations carried out by pneumatic piercing, are in fact carried out with the required precision. Provided, of course, that the machine itself has design features conducive to this accuracy. A pneumatic piercing machine of suitable design, even in the hands of an inexperienced Operator, allows for accurate making boreholes over a typical distance and in typical ground conditions. In more difficult ground conditions and over longer distances, a greater range of experience will of course come in handy.

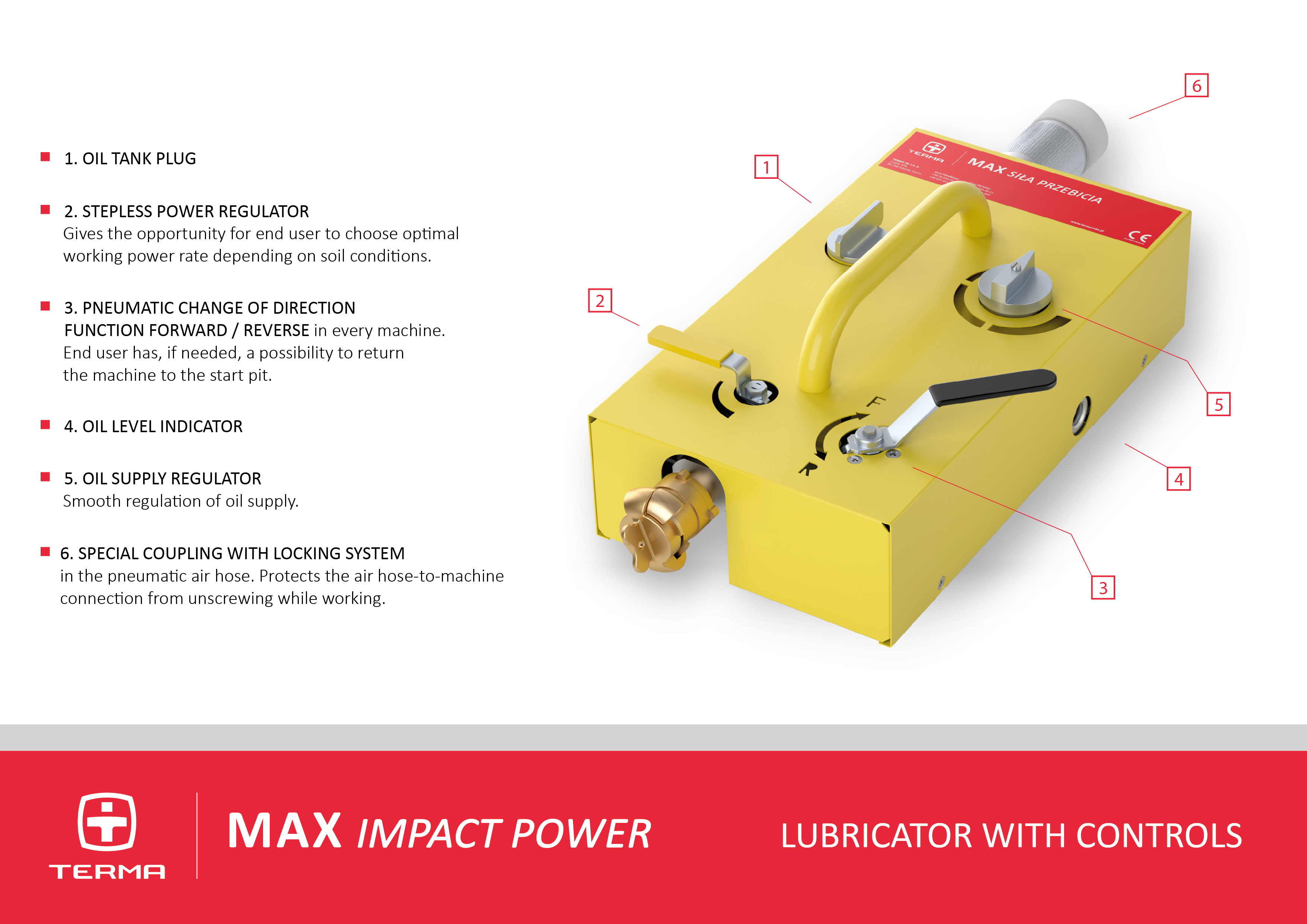

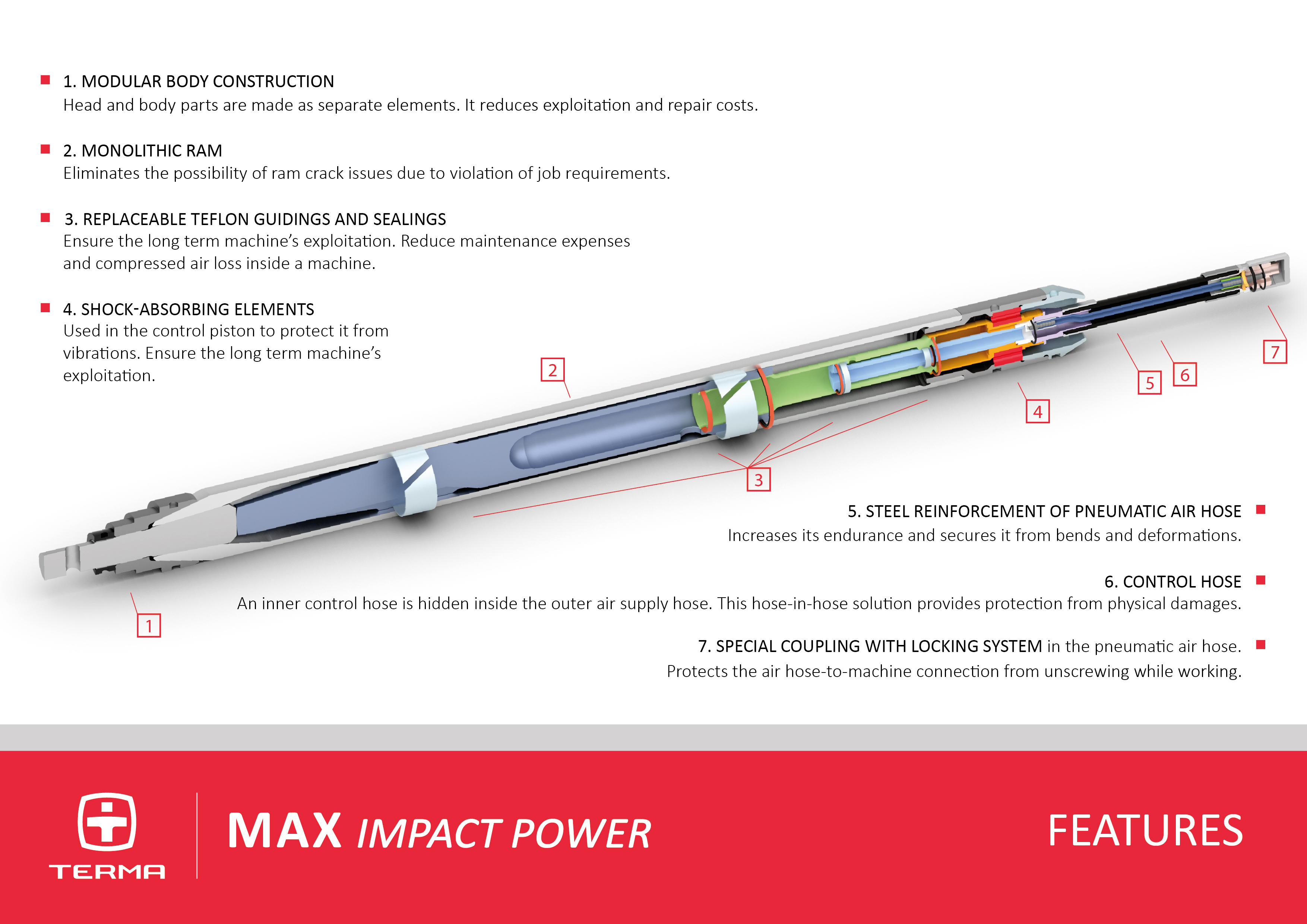

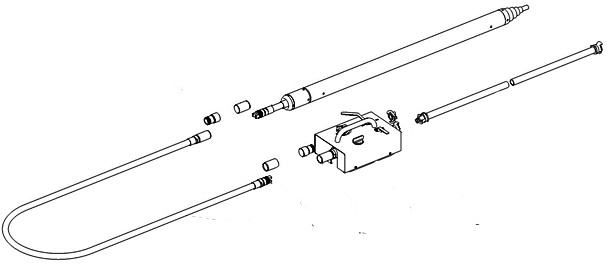

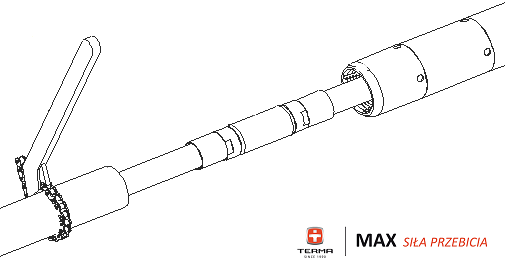

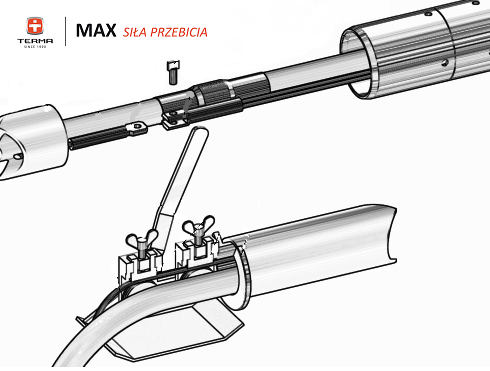

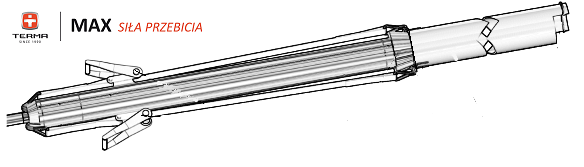

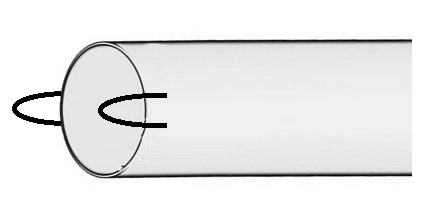

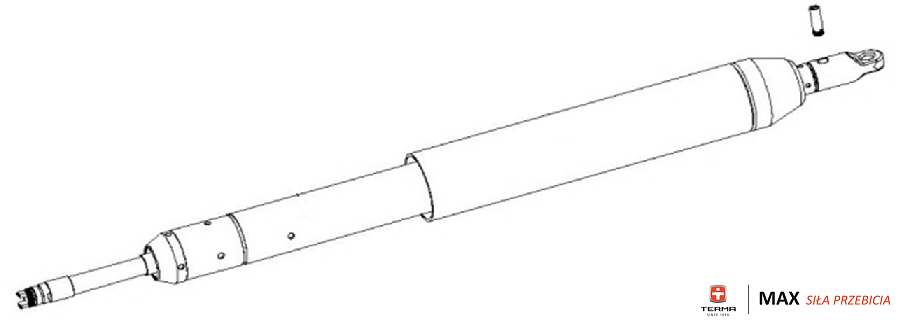

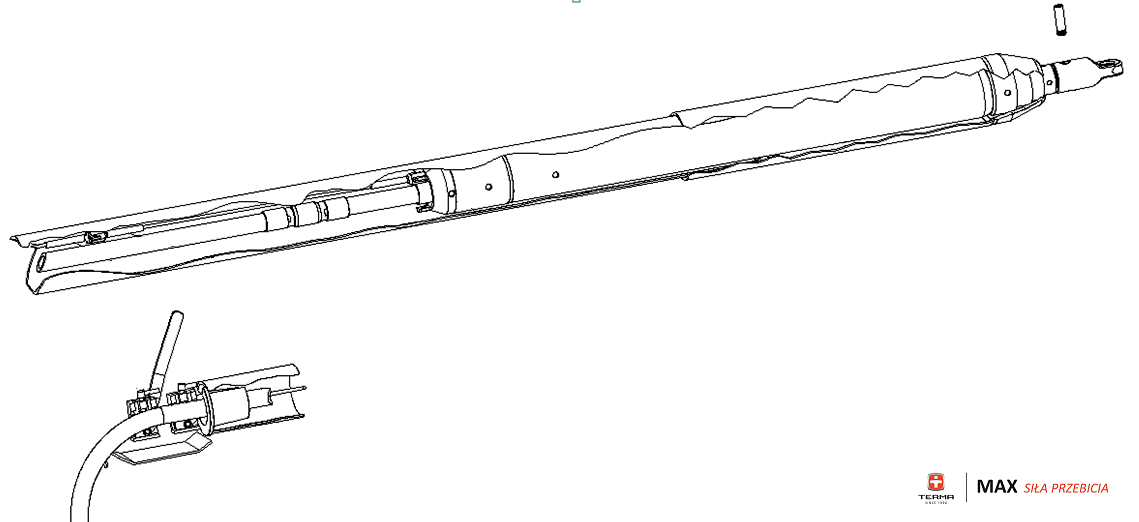

The construction of a mole is less complicated, compared to a drilling rig or other machines used in trenchless techniques. How such a typical mole is built is shown in Figure 2. Thus, the cost of making and buying such a device is very low, if we compare it to the cost of buying other machines. To power the mole, it is enough to connect it to a source of compressed air. This air, as a result of a strictly ordered flow inside the mole, makes the piston, otherwise known as a beater, strike a certain surface giving the machine a movement in the direction of FORWARD / BACK, set by the Operator.

Figure 2

Construction of the piercing machine

The mole will allow the installation of plastic pipes, with diameters from 50 mm to 225 mm. The larger the diameter of the pipe to be installed, the larger the mole should be used. From our practice, the most versatile machine until a certain point was a mole with a diameter of 130 mm, in our case called MAX K130S. It is mainly used for the installation of pipes with a diameter of Ø110 mm and Ø125 mm. With its help, it is also possible to install pipes of smaller diameters, for example, Ø75 mm. Recently, however, there has been a noticeable tendency to use moles for dedicated diameters of the pipes to be installed, due to less lead time and reduction of logistical problems. And so: for pipes with a diameter of Ø50 mm, it is increasingly common to use not a machine with a diameter of 130 mm, but a smaller, lighter mole, designed precisely for this particular diameter, that is, a machine with a diameter of 65 mm, in our case it is MAX K65S. You can, of course, use the MAX K130S here, but what's the point if it's a much larger, much heavier machine, requiring more air, and therefore generating higher installation costs. The growing number of installations requiring the trenchless method, especially the use of a mole, is causing installation companies to equip themselves no longer with a single universal machine, but to expand their fleet with several machines of different caliber.

With the help of a mole, it is also possible to trenchless installation of steel pipes with diameters from 133 mm to 406 mm. Here we have exactly the same relationship as in the case of PE/PVC pipe installation: the larger the machine, the larger the diameter of the steel pipe can be installed.

A source of compressed air, usually in the form of a portable compressor, is required to work with a mole. And that's basically all we need. Being a novice Installer, you can still use a starting platform, in order to make it easier to align / aim the mole at the target point.

You need to make a starting pit, with a length long enough to fit our piercing machine in it, along with a section of the pipe to be installed. An end pit of similar dimensions should also be made, although if there is not enough space for it, this is not necessary, because in the event of anything you can always withdraw the mole to the starting pit, making the installation itself while the machine returns, or manually, after withdrawing and removing the mole from the starting pit.

And that's pretty much it, if we were to discuss the use of pneumatic piercing machines so briefly. To summarize: the mole is used wherever we have to deal with short sections of installations, usually under an existing road, sidewalk. Typical installations are in the range of 5-20 meters. The mole really requires a minimum of space adjacent to the planned installation. The mole is mobile, even a passenger car is sufficient to transport it to the site. The mole is low-cost to purchase and low-cost to operate. It will provide the desired efficiency and accuracy. The speed of installation in typical ground conditions is 0.3-1.0 m/min. It is easy to use, preparing it for operation costs little time. It is applicable to both pressure and gravity installations. The cost of making each meter of installation, given the above features, is relatively low, compared to the other method under consideration, which is the horizontal directional drilling (HDD).

HORIZONTAL DRILLING RIG

A method otherwise known as horizontal drilling, HDD drilling. This is a machine designed to perform installations over much longer distances, reaching hundreds of meters. A typical diagram of such an installation is shown in Figure 3.

Figure 3

Typical application of a horizontal drilling rig

The construction of such a machine is much more complex, making the cost of purchasing such a machine many times higher than a mole. The machine has a hydraulic drive, which, among other things, gives the elements responsible for the implementation of the installation a rotary motion, responsible for drilling, and a reciprocating motion, responsible for the linear movement of the drilling and pushing head. The drilling rig has a sophisticated hydraulic control system, thanks to which the drilling process takes on an almost automatic character. Successive rods pressed into the ground are automatically fed from the hopper, forming the drill pipe. One operator is directly at the machine and controls its work, and the second operator, using a locator, reads the current position of the drilling-pushing head in the field. The drilling machine is a controllable device, it is possible to change the direction of drilling at any stage of its operation, which allows you to avoid obstacles the existence of which we know (water reservoirs, river). Such a machine is most often made self-propelled, moving on wheels equipped with tracks. Heavy-duty trailers are used to transport the machine to the work site.

The installation of pipes with an HDD drilling rig consists of three stages: the drilling of the pilot, i.e. the drilling from the starting point to the destination, the reaming of the hole made as a pilot to increase the diameter of the drilled hole, and the actual pull-in of the pipeline. These three stages are accompanied by the continuous feeding of mud, which has the following tasks: excavating the soil, transporting spoil to the surface, reducing friction resistance, cooling the pilot and product pipelines, sealing the borehole walls and stabilizing the borehole. Drilling rigs are most often used for pressure-type installations, although gravity-type installations can also be built using them. Drillers are used to install pipes with diameters of hundreds of mm and more.

In a brief summary of this method, we can say that: HDD drilling machines are suitable for installation at much greater distances than moles and at much larger diameters. At smaller distances, their use is highly unprofitable. It is true that with their help it is possible to perform some installations that are possible with the help of a mole, but the cost of such installation will be much higher than with the help of a mole. Not all such installations that can be done with a mole are within the reach of HDD drilling rigs, mainly because of the larger amount of space required. Drill rigs use a mud system, which, working in open circulation, negatively affects the environment in the vicinity of the work being carried out. The machine itself requires a much higher cost, both for purchase and during operation. The machine is definitely not a mobile one.

CONCLUSION

The summary will be as follows: each of these machines is dedicated to a specific group of work. Certain types of work can be done with both machines and technologies. And certain types of work are possible with only one of them. We, as a manufacturer of piercing machines, have seen a significant increase in demand for mole machines for several years now. And as citizens of our country, we are seeing more and more work being done around us using trenchless methods, which just a few years ago would certainly have been done using the traditional method of open excavation. And this makes us very happy, not even so much as manufacturers of machines, but as users of existing infrastructure, which will serve us for longer if we try to interfere with it as little as possible, precisely by using trenchless techniques.

Mole vs. hydraulic rod pushing machine

Any comparison of several trenchless technologies against each other misses the point. The various methods have different areas of application, costs and lead times. A good example of this would be to compare the technologies of horizontal drilling rig and molester. It is impossible to say which one is better, more advantageous. And this is because each of them has a different purpose, application. With a mole, we will not do an installation of hundreds of meters in one section, while having to overcome terrain obstacles (such as a river). To carry out such an installation we will go for an HDD drill rig. If, on the other hand, we have to perform a simple installation section of 20 meters, running under a local road, we will not use an HDD drilling rig for this purpose, due to the much higher ( not profitable in the end) cost and greater complication of work with such a device, and we will just use the cheaper option - an impact mole.

However, such a comparison can be made by comparing two types of equipment, both of which have almost identical application, purpose. We are talking about comparing a simple hydraulic rod pushing machine, without functions of locating and control, with another simple machine such as a pneumatic mole. Both of these devices are dedicated to the same types of trenchless installations: for a distance of 5-20 meters, you need to install a casing pipe under the existing pavement, without disturbing it.

Which of these two devices should you choose? Which is more effective? Which is more versatile? Let's try to answer this question by objectively comparing their respective parameters. We rely on opinions coming to us from our customers who have used both techniques. We also rely on opinions found online, in industry forums and social networks.

1. Equipment

A mole needs compressed air. Almost every construction company has a mobile compressor and powering a mole should not be a problem here. However, let's look at a comparison with the hydraulic rod pushing machine. Regardless of the machine we are installing, for both cases we need to make a starting pit and an ending pit. For this we need an excavator or at least a mini-excavator. This excavator can in turn be the power source for the hydraulic rod pushing machine. That is, when doing a mole installation, we need to have three machines on site: an excavator, a compressor and a mole. Working with the hydraulic rod pushing machine, on the other hand, we only need an excavator and a jacking machine.

The total cost of the jacking equipment, is much less in the case of the hydraulic rod pushing machine, if we look at it in such a way that we start in the construction market and have to equip ourselves from scratch.

Advantage of the HYDRAULIC ROD PUSHING MACHINE.

2. Installation of the device before starting work

Both devices are of similar weight. Both require a few minutes/ten minutes (depending on the terrain) to spread out on the site, connecting the various components. The mole, before it can be let loose into the ground at full power, must penetrate at least half of its length. Only then will the cylinder catch traction with the ground and the machine with all its power hit the piston (beater) on the anvil, will go forward. Before this can happen, the mole must be helped to achieve this adhesion by, among other things, reducing the amount of air supply and pressing it against the ground.

The hydraulic jacking machine, in turn, must be properly seated and anchored in the starting pit. Often it is not enough to support its rear against the rear wall of the starting pit and during the first centimeters of jacking, the machine will change its position under the influence of its own head thrust. Both technologies can be described as relatively easy and quick to install, compared to other, more advanced technologies.

Both technologies have no special requirements. We have a tie.

3. Speed of performing installations

Here, at first glance, it is difficult to find a single, clear favorite. In order to obtain reliable data, individual piercing using both types of machines would have to be carried out in exactly the same ground conditions. The speed of piercing through the ground, on a global scale, can be assumed to be comparable in both cases. However, in the case of the hydraulic rod pushing machine, the piercing process is interrupted, due to the need to add/add more rod segments. In addition, in case of the hydraulic rod pushing machine, the pipe itself is pulled in while the jacking head is reversing (pulling back). In case of moles, it is extremely rare that the pipe is pulled in during the mole's return to the starting pit. The mole usually pulls in the pipe in the very first operation, pulling it directly behind the device. Remember, however, that in the final analysis of the implementation of the installation, time does not play such an important role. Unless the difference in times would be 100% or more. In our case, this is not the case, whether the installation will take 20 or 30 minutes, it does not really matter. Nevertheless, the mole has an advantage here, mainly because it does not have to interrupt the work as it does when working with the hydraulic rod pushing machine and having to add/add more rod segments.

Advantage of the IMPACT MOLE.

4. Handling during installation

In this area, the mole definitely wins. All we have to do is direct it properly, start it up, check that it hasn't changed its trajectory as it plunges into the vertical wall of the starting pit, correct it if necessary, and let it go on. And all that remains is to wait for it to reach the target pit, checking only from time to time to see if the air hose plunges behind the mole, indicating the progress of piercing. You can stand on the surface of the ground, and try to locate where the mole is beating the ground at any given time. With the hydraulic rod pushing machine, unfortunately, you have to stand at/on the machine all the time, and depending on the stage of installation, add/add more rods, and stop/start the pushing machine itself.

Advantage of the IMPACT MOLE.

5. Accuracy

This is undoubtedly the most important parameter. The success of our work depends on the accuracy. In this case, the mole has an undoubted advantage, which is the impact. This impact allows you to overcome hard obstacles on which the hydraulic rod pushing machine will fall. The rod of the hydraulic rod pushing machine in such a case will bend and the entire jacking will change direction, come out off target. The mole, on the other hand, equipped with a stepped head, will more easily cope with a hard obstacle. Occasionally, of course, there are situations when the mole, having encountered loose and soggy ground, will not cope with such an installation, and in such a case it remains to ram steel pipe. In the vast majority of jobs, however, more important is the ability to overcome hard obstacles, which the mole can handle perfectly well with high accuracy. The hydraulic rod pushing machine, on the other hand, will not be able to cope with a hard obstacle or will succumb to it at the cost of a significant drop in accuracy.

Significant advantage of the IMPACT MOLE.

6. Versatility

Due to the impactive nature of their work, moles perform well in the vast majority of cases and soil types. In rocky soils and in very hard soils, the impact allows to perform the installation with the intended accuracy. The hydraulic rod pushing machine will not cope in such situations, we will not perform the installation with it in such cases, we will have to reach for an alternative solution. In wet, clay soils, the hydraulic rod pushing machine will prove better, but in turn the mole gives an effective alternative in the form of the ability to ram a steel pipe. In most typical soils, both devices will do just fine.

Advantage of the IMPACT MOLE.

Summary:

It is best to put them in a table. We encourage all comments and discussion on the topic.

|

CATEGORY

|

MOLE

|

ROD PUSHING MACHINE

|

|

Equipment

|

|

😊

|

|

Installation of the device

|

😊

|

😊

|

|

Speed of performing

|

😊

|

|

|

Handling during installation

|

😊

|

|

|

Accuracy

|

😊

|

|

|

Versatility

|

😊

|

|

|

TOTAL:

|

5

|

2

|